Introduction

The development of the Cycle-Tempo software has been ongoing for a very long time and started in the late 1970s. Many different versions marked its evolution as Cycle-Tempo has been running on various computer types and several operating systems. A brief summary of this long story is provided and a sneak preview of the upcoming releases of Cycle-Tempo concludes this report.

1970’s to 1985

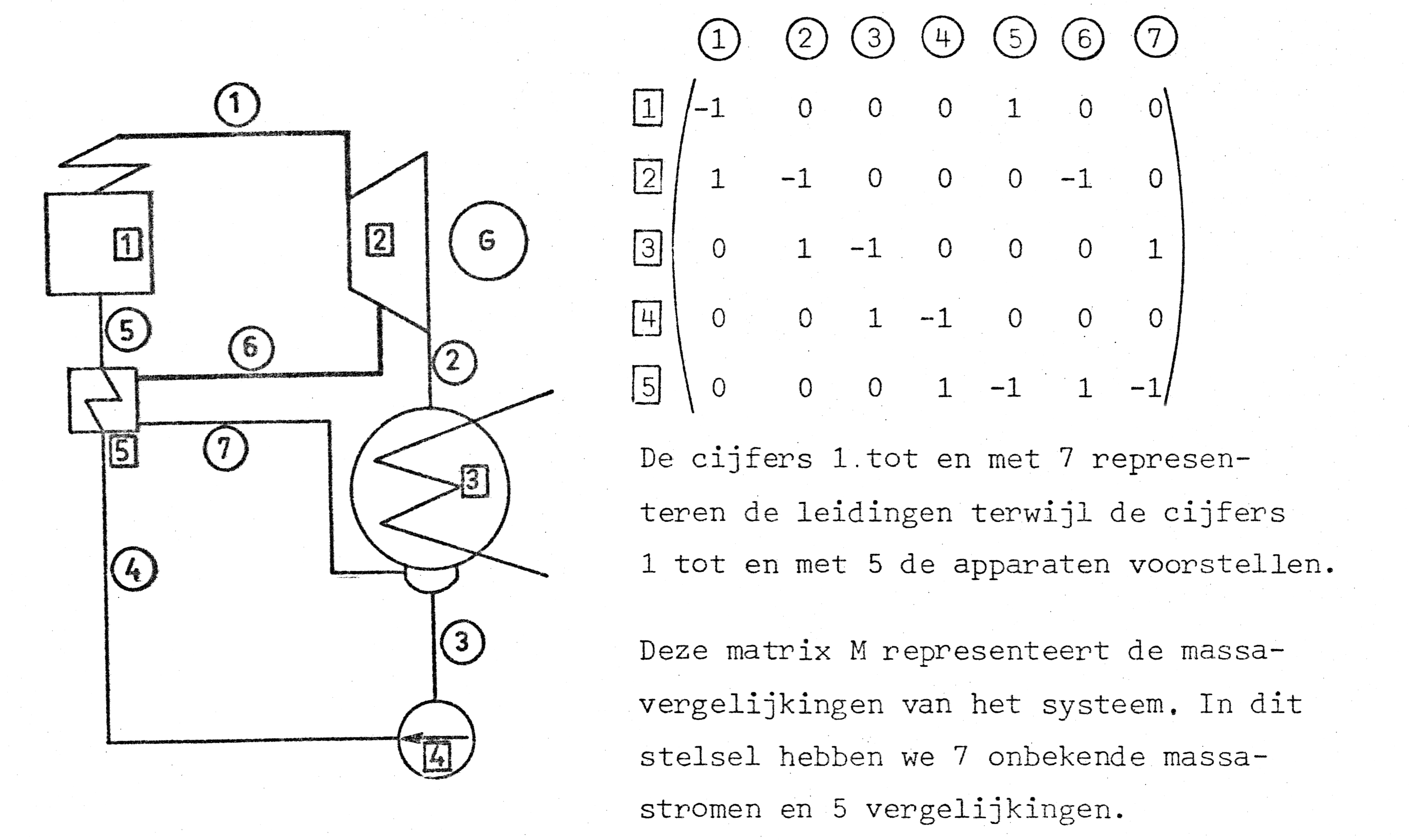

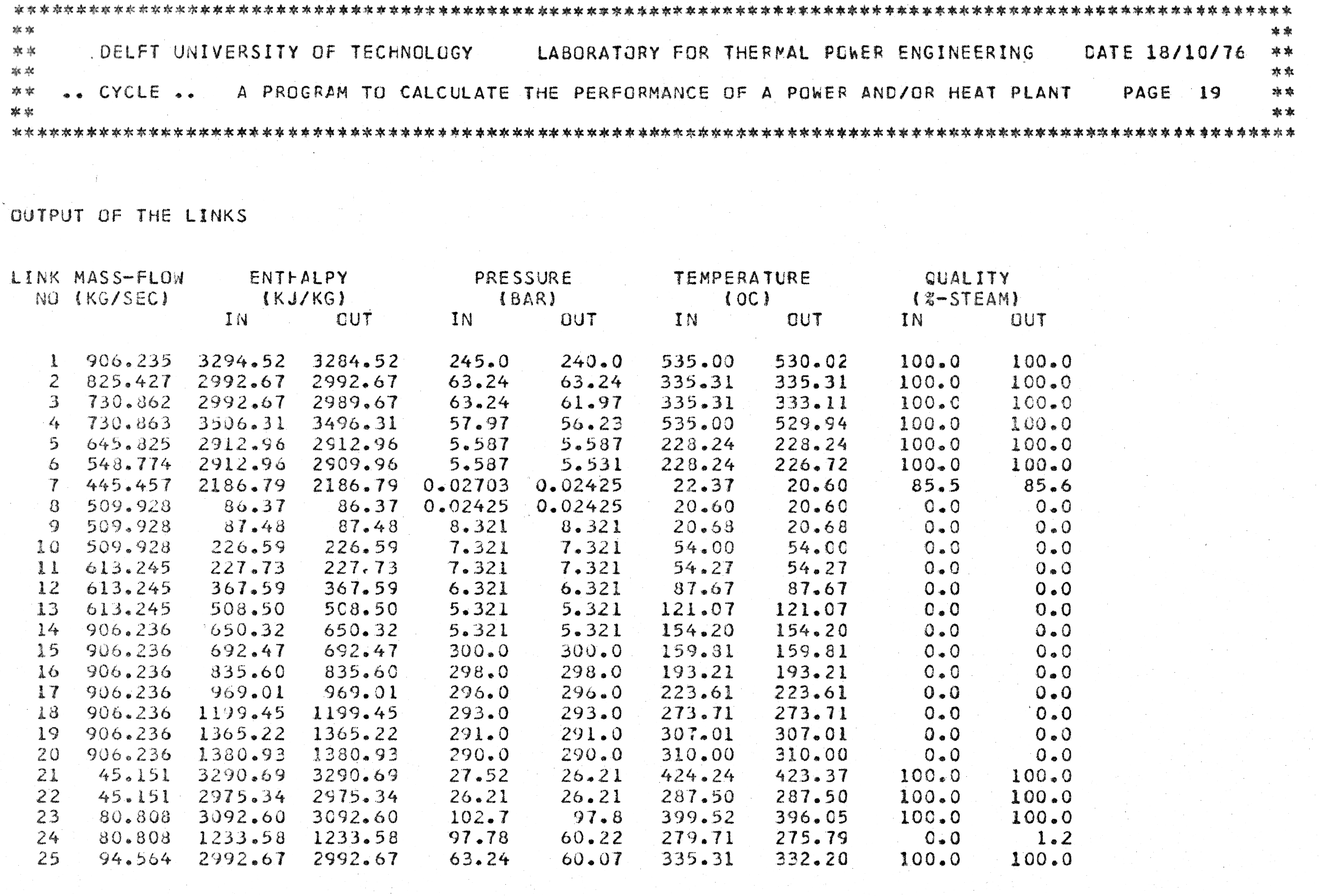

The oldest source code listing that resembles pieces code of Cycle-Tempo came to light in the early 1970’s. This first attempt at solving the mass and energy balances of a complex energy conversion systems was written in PL/1, which is an abbreviation of Programming Language 1, a programming language developed by IBM. PL/1 was meant to combine COBOL from the business world and FORTRAN from the scientific world, but it never became successful. Later, FORTRAN IV was used to develop the first official version, which was just called CYCLE at that time. CYCLE was succeeded by CYCLE II in 1976.

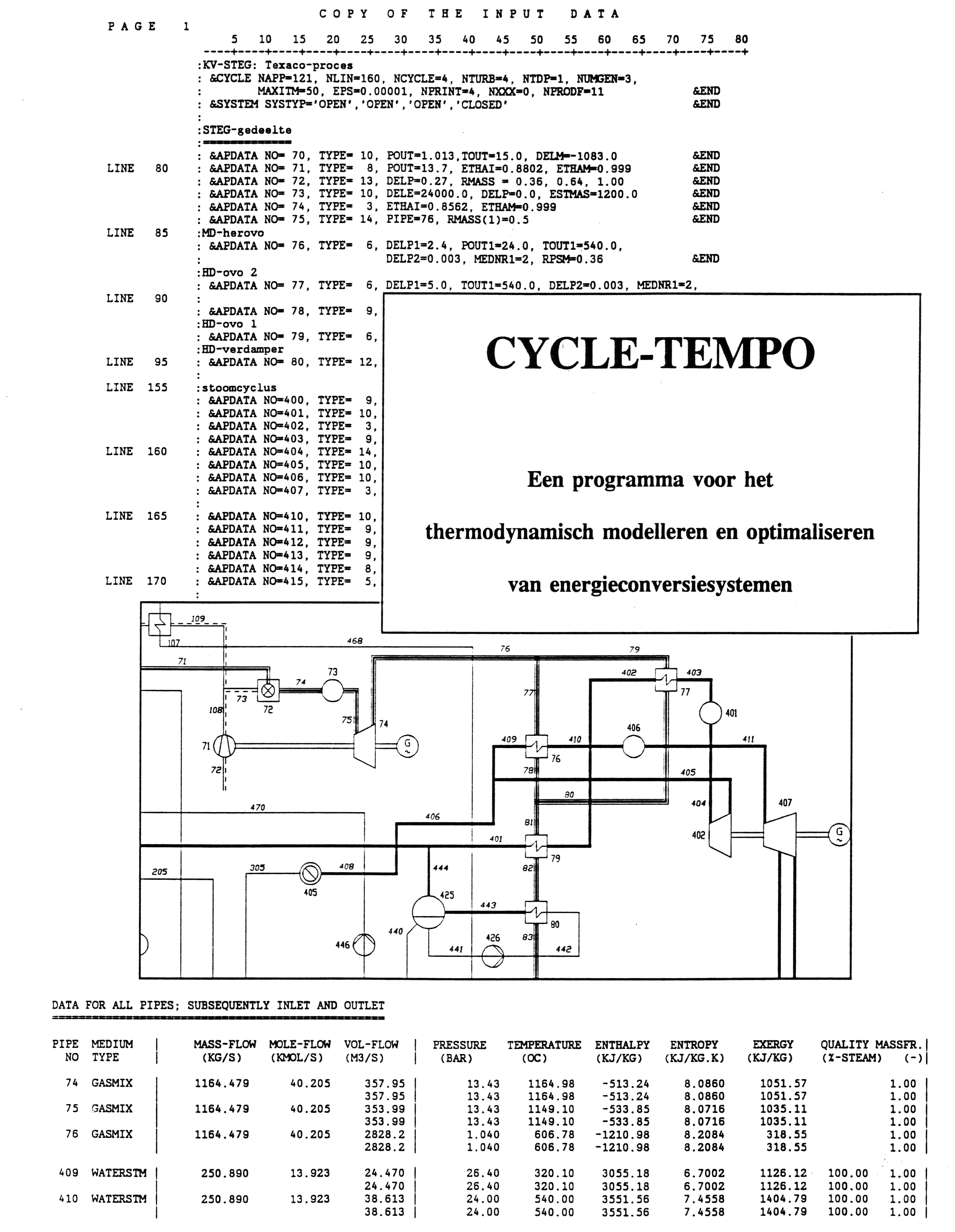

Cycle II allowed modelling water/steam cycles containing boilers, reheaters, steam turbines, feedwater heaters, condensers, contact heaters, pumps, and junctions/splitters. It ran on an IBM mainframe in batch-mode, meaning an input dataset had to be composed on punch cards containing the system configuration and design parameters (like pressures and temperatures). Together with the program code, this had to be submitted to the mainframe and, if you were lucky 😊, printed output containing the output of the calculation was ejected to your hands by the machine. In the most common situation, the output just contained a list of error messages and you had to correct your mistakes and resubmit your dataset.

In 1981, CYCLE III was born as a deliverable of a PhD project (J.A. Miedema, CYCLE: a general code for thermodynamic cycle computations, studies of cogeneration in district heating systems, 1981, Delft University of Technology). Among others, thermodynamic property calculations of ideal gas mixtures and models of a combustor, a valve, and a drum were added to CYCLE III, making it possible to model systems with combustion and gas turbines. At that time, also industrial companies became interested in the software and several copies of CYCLE III were purchased.

1985 to 2000

In the meantime, computer terminals made their appearance and replaced punch card machines, which was a great progress (and relief!). Computer terminals were devices consisting of a screen and a keyboard remotely connected to the mainframe that allow data to be entered, retrieved, and displayed. Around that time, 1986, the author started working as a computer science engineer at the Laboratory of Thermal Power Engineering of the Delft University of Technology (TU Delft) and was involved in the further development of CYCLE, a year or so later.

During that time, quite a few improvements were made to the software and many extensions of its capabilities were achieved. For example, the possibility of simulating open cycle systems was added, which greatly increased the flexibility of the software. In the Laboratory for Refrigeration and Climate control of the Mechanical Engineering faculty, facilities and components were added to make it possible to model refrigeration systems, e.g., absorption refrigeration. This was meant to be the new version of CYCLE, namely CYCLE IV. However, this work was not finalized at that time, probably due to a combination of lack of further interest and continuity of capable people who were able to carry on this work to good effect. The current Ziegler-Trepp NH3/H2O model for the calculation of the thermodynamic properties of ammonia/water mixtures is one of the remains of that work.

For several years there had been a close collaboration with TNO, a Dutch institute for applied research. Within the framework of this collaboration, the calculation of potassium cycle system was implemented. TNO became also responsible for the commercialization of CYCLE and took care of the marketing and distribution of the software.

At the same time, other important extensions were being worked on. Chemical equilibrium calculations were improved and already at that time a model of a reformer and a fuel cell were added. Modelling systems with molten-carbonate (MCFC) and solid oxide (SOFC) fuel cells became then possible. These models are still the base of the reformer and fuel cell models that are available in Cycle-Tempo nowadays. To give credit to the possibility of modeling open cycle systems, it was considered to change the name of the software from CYCLE to TEMPO, an acronym for Thermodynamic Energy systems, Mass flow calculation for POwer processes. However, the name CYCLE had already become widely known by then, and therefore it was decided to rename the software to CYCLE-TEMPO, which remained unchanged to this day, although now written as Cycle-Tempo.

The costs of using the mainframe were increasingly passed on to departments and laboratories. Consequently, and having earned some money from selling CYCLE, the Thermal Power Engineering laboratory bought their own computer system consisting of two mini computers. These systems were IBM RT systems running on the AIX operating system, an IBM UNIX dialect based on AT&T’s UNIX System V. The systems were originally connected to 5 terminals, and, over time, a significant number of personal computers were used as terminals as PC ownership became widespread and commonplace on desks.

CYCLE-TEMPO was ported from the main frame to the IBM RT and as a result CYCLE-TEMPO 2.0 was born. Also, the code itself was for a large part ported to FORTRAN 77, which allowed more structured programming by almost entirely eliminating the need of GO TO statements and many more relevant enhancements. Later, after the release of Fortran 90 and Fortran 95, more and more features of these modern programming languages were added to the code.

At that time CYCLE-TEMPO was still running in batch-mode and without graphical user interface (GUI). We thus built an AutoCAD library with component symbols and line types for component connections to create drawings of process schemes in AutoCAD, and spent much time making these drawings and keep them synchronized with the calculations that were carried out. Would not it be much simpler if required data could be entered directly from the process diagram and the configuration of the energy system could be retrieved from the process flow diagram? Yes, of course! Investigations were started to figure out if and how a GUI could be realized in such manner. A first attempt to create a GUI was carried out on the IBM RT system by TU Delft students of the Mathematics & Computer Science faculty. They employed CGE (Configurable Graphical Editor), an inhouse software of TNO, but the attempt was unsuccessful.

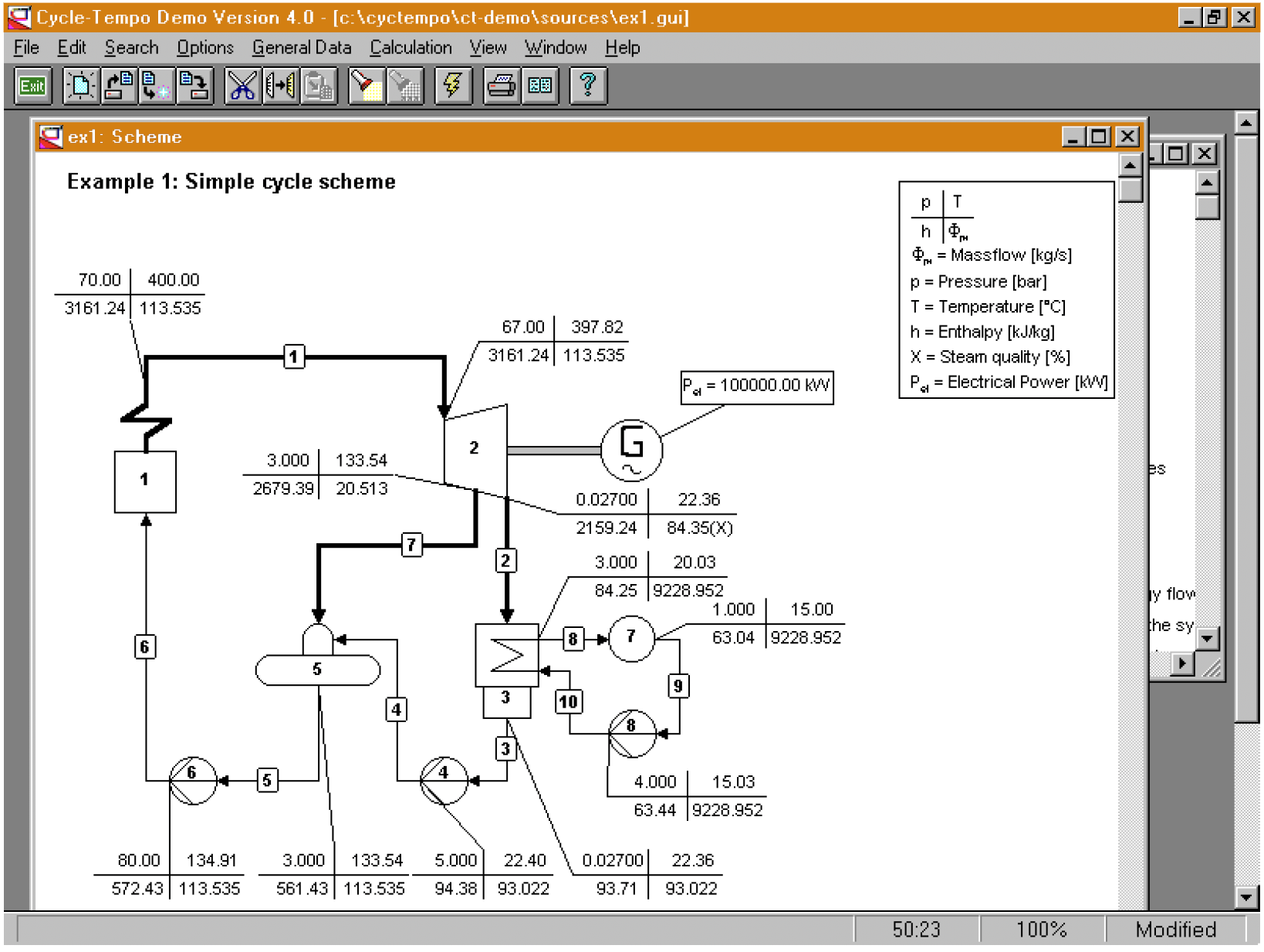

Building on the experience of this first attempt, in 1993 a GUI was coded using Borland C++ such that it could run on a Windows 3.1 PC. The OWL library in Borland C++ gave the GUI a full Windows 3.1 look and feel, which was nice because many people were already used to it. In the end we were able to develop a basic version of a GUI that met the minimum requirements for process flow diagrams of energy conversion systems, and that allowed to enter the desired process data to carry out the calculations. With the help of a master student of the Mathematics & Computer Science faculty department, the GUI, internally known as GUIDE (Graphical User Interface for Designing Energy systems) was developed further.

A problem was that the calculations itself could not be carried out on a PC, because at that time Fortran programs and compilers required more RAM memory than commonly possible on 16-bits computer systems. A first solution was to have GUIDE create a dataset for a CYCLE-TEMPO batch run on the RT system. The dataset was then sent from the PC to the RT using Kermit, a file-transfer and -management protocol, which in turn sent the output of the batch calculation back to the PC.

In the 90’s of the previous century, many developments were going on in parallel. Aside from what is mentioned above, in the meantime many new energy system component models were added to the program, such as a type of gasifier, the compressor, the chemical reactor, components for gas treatment (cleaning, drying, saturating), fuel cells (alkaline – AFC, phosphor-acid – PAFC, proton exchange membrane fuel cell – PEMFC, also named solid polymer fuel cell – SPFC), an extended condenser model with advanced off-design features, etc. Exergy analysis became possible by adding the feature that allows to calculate all exergy flows in a system and the exergy efficiencies of the components. A team of several scientists, PhD students, software scientific software engineers, and master students were all working together doing research and extending Cycle-Tempo to fulfill their research requirements.

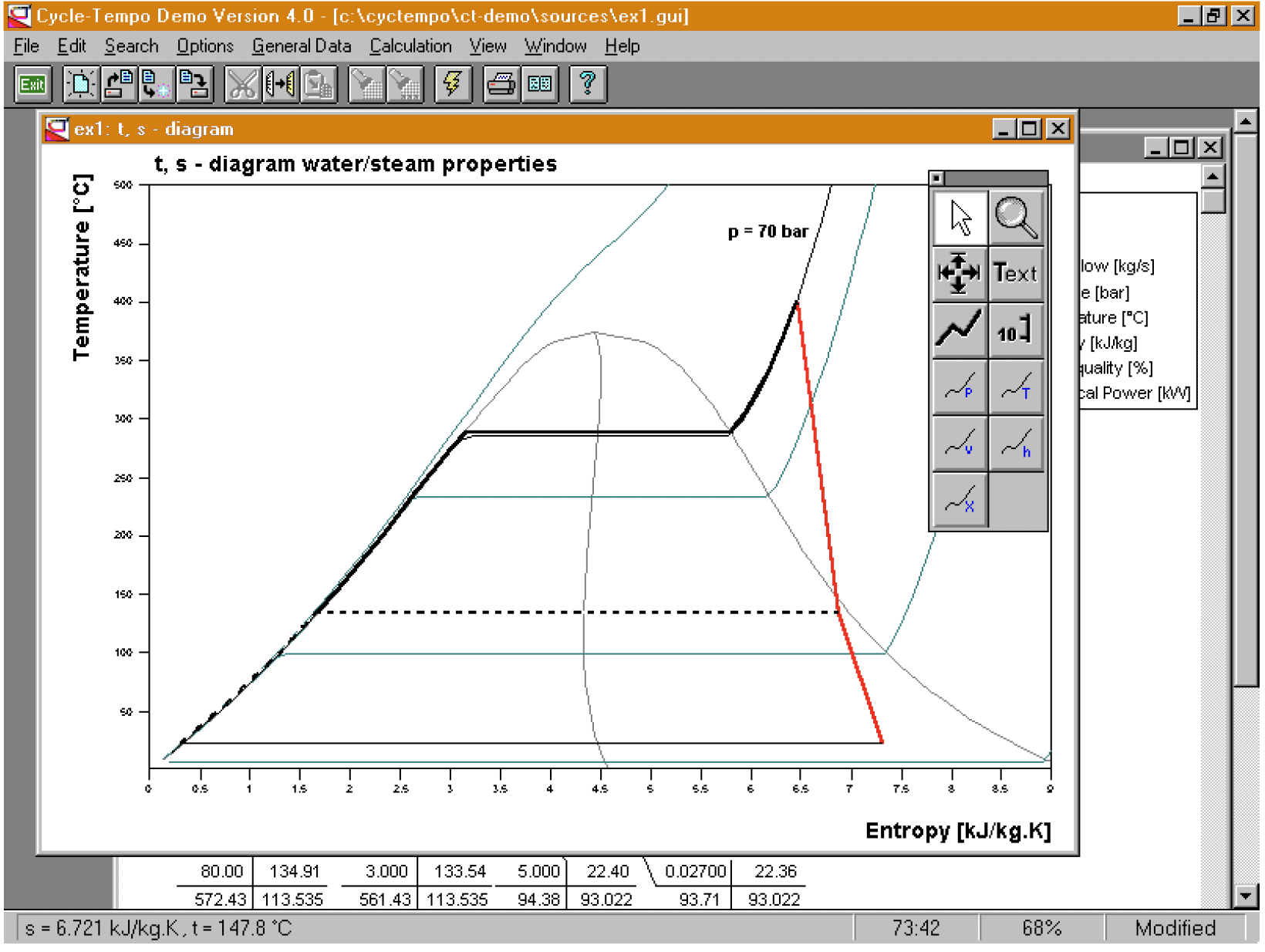

Finally, also during the 90’s, TNO improved the modeling capabilities for refrigeration systems, like vapor compression cycles, absorption refrigeration cycles, and heat pumps. An early version of REFPROP (version 4), a library for the estimation of fluid thermodynamic properties, was added by TNO, with data for a large number of refrigerants. Thus, evolving through CYCLE-TEMPO 3.0, the last century ended with Cycle-Tempo 4.1, showcasing a modern graphical user interface and even a gas turbine library.

2000-2022

In the early 2000s, the GUI was ported to a 32-bit system, therefore making the software suitable for use on a Windows NT platform, later followed by Windows 2000, XP, Vista, Windows 7, 8, and 10. Currently, Cycle-Tempo 5 runs on all Windows 11 platforms, including 64-bits and the latest Windows Server systems such as Windows Server 2019.

In the meantime, the collaboration with TNO had ended and support, marketing and distribution had returned to the developers at TU Delft. Existing models were continuously improved and a model of a Direct Carbon Fuel Cell (DCFC) was added. Aside from that, driven by research needs, these years were focused on developing capabilities for working fluids of organic Rankine cycle systems.

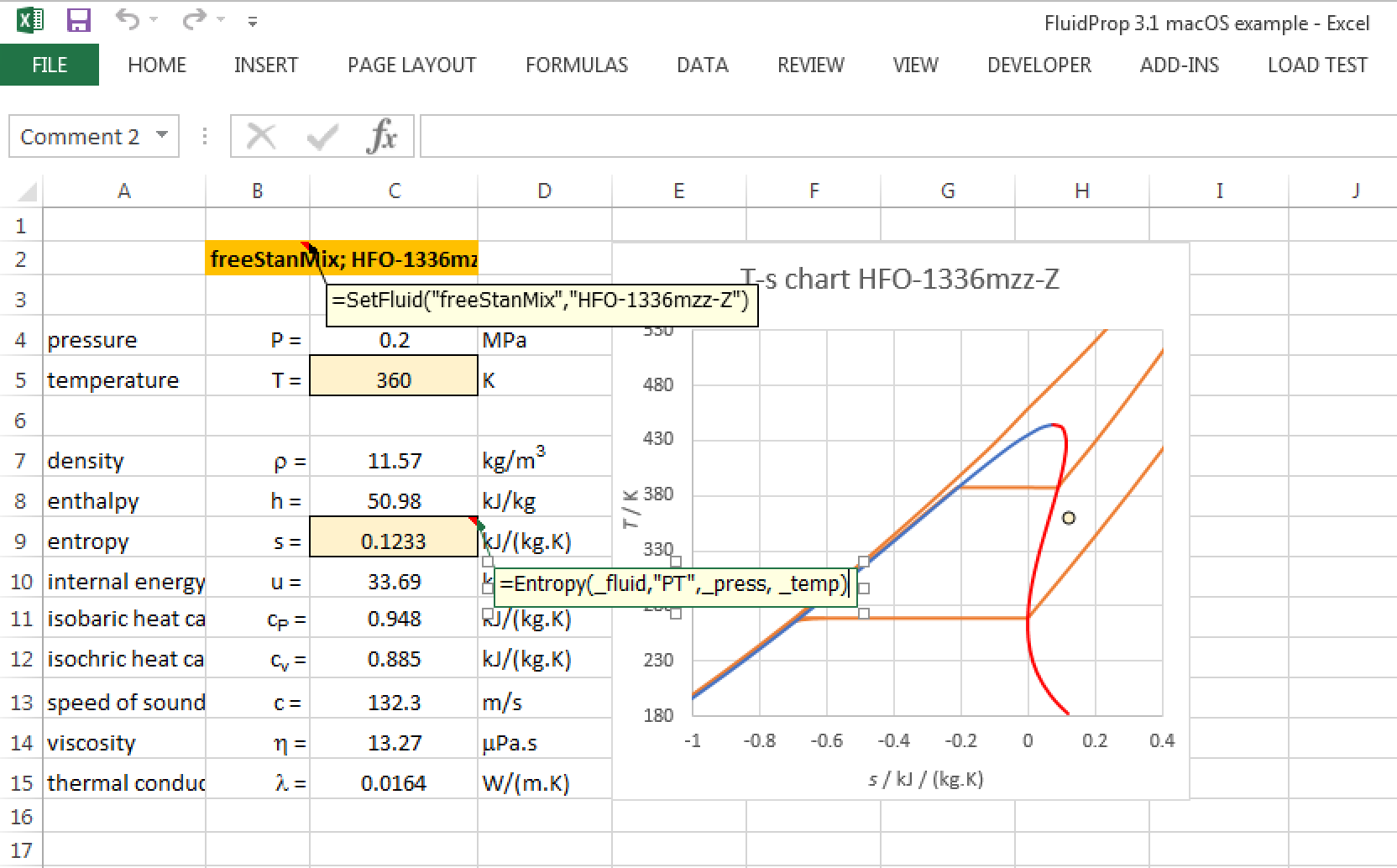

FluidProp, a software package for the calculation of thermodynamic and transport properties of fluids was developed at TU Delft separately from Cycle-Tempo. FluidProp is in fact an encapsulation of different existing packages for the calculation of thermodynamic properties with a number of additional features. Packages like TPSI, StanMix, GasMix, PCP-SAFT and IF97 became all available through the common FluidProp interface such that the user would not need to learn anything particular to any of the various fluid property modules. NIST REFPROP was also added to FluidProp. In turn, FluidProp was coupled to Cycle-Tempo and as such all fluids and fluid models / equations of state implemented in FluidProp became available to Cycle-Tempo within a typical client server architecture.

A new website was developed and released and it included a web shop for direct purchase and payment of software products and professional licensing software was incorporated into both Cycle-Tempo and FluidProp. Meanwhile, in 2022, the website has been renovated and the licensing system was replaced with a modern license key system for Cycle-Tempo.

The innovative and superior textbook Thermodynamics: fundamentals and engineering applications by William C. Reynolds and Piero Colonna, was developed by leveraging on a close collaboration with Asimptote as far as many of the illustrations, exercises and more are concerned. It was released in 2018 and can be purchased from, among others, the web site of Cambridge University Press and Amazon.com. FluidProp and Cycle-Tempo allowed to generate the majority of the useful tables, wonderful figures, calculation examples, and exercises that are sprinkled throughout the entire book.

2023-

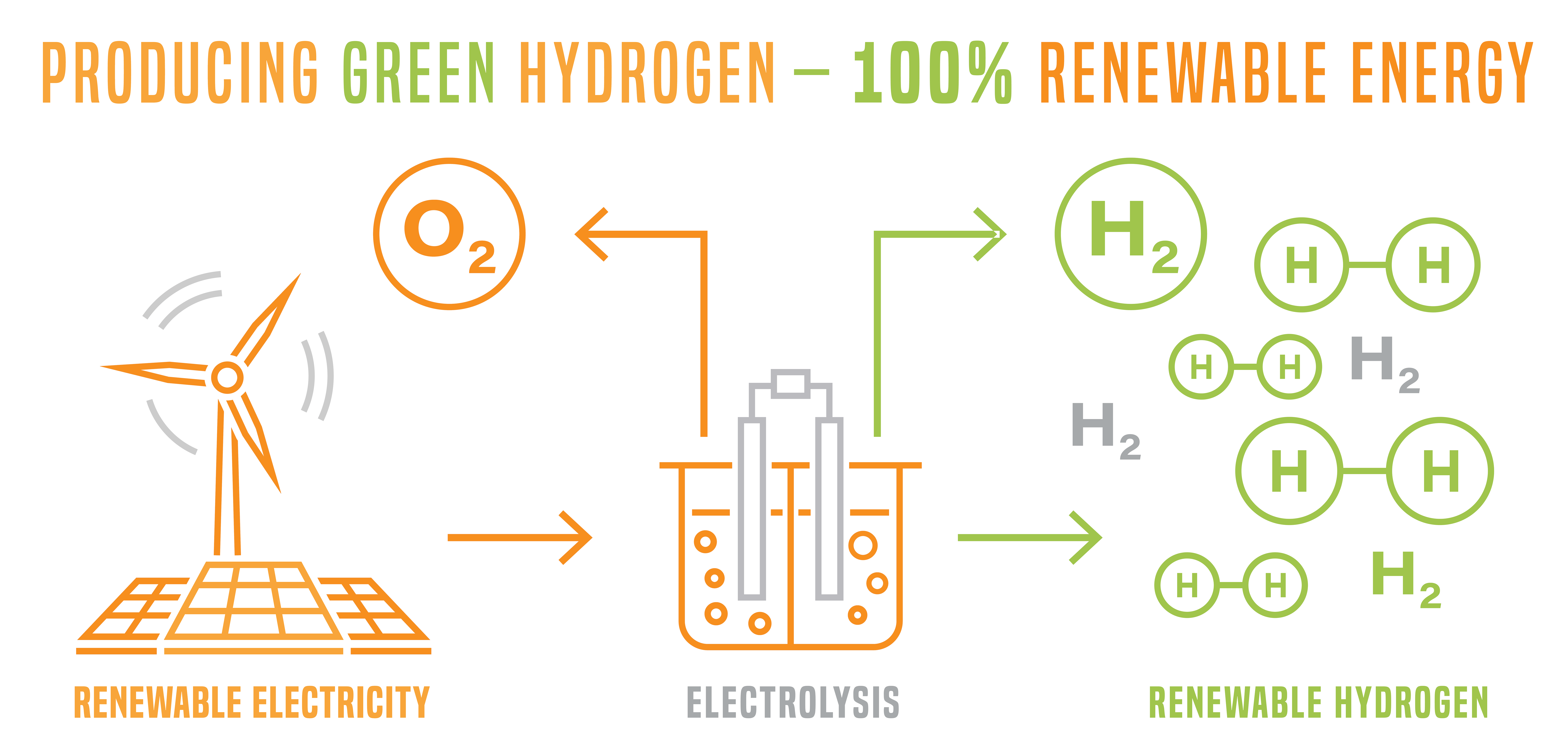

Solar and wind energy play a significant role in the transition to a cleaner, more sustainable global energy system. Both solar and wind energy are considered renewable sources of energy because they can be replenished naturally. However, their availability can vary significantly over short periods of time, which can make it challenging to rely on them as the primary source of electricity.

To address storing excess solar and wind energy, one of the potential developments, next to batteries or pumped hydroelectric storage, is electrolysis. An electrolyser or a reversible fuel cell produces hydrogen gas out of electricity, which can be stored and reused to generate electricity (with a fuel cell) or burned to produced heat.

In order to satisfy the need to calculate the mass and energy balances of electrolysis systems, an electrolyser model for Cycle-Tempo is under development. As a first step, this model is limited to high temperature solid oxide cells (SOFC’s). It covers steam electrolysis, CO2-electrolysis and co-electrolysis.

What’s next? For the foreseeable future, we consider Software as a Service (SaaS) as an attractive addition to our software portfolio. SaaS is a software delivery model in which a software application is hosted by a third-party provider and made available to customers over the internet. SaaS providers typically host and maintain the infrastructure, security, and maintenance of the software, while customers pay a subscription fee to access and use the software on a monthly or annual basis. One of the main benefits of SaaS is that it allows customers to access software applications and data from any device with an internet connection, without the need to install and maintain software on their own computers or servers. This makes it an attractive option for companies and universities, as it reduces the upfront cost and technical expertise required to run software applications. Another advantage of SaaS is that it allows for frequent updates and new features to be rolled out to customers without requiring them to manually update their software. This means that SaaS customers can always access the latest version of the software, with new features and improvements being made available on a regular basis. Overall, SaaS is a popular and convenient way for companies and universities to access and use software applications, without the need for upfront costs and ongoing maintenance.

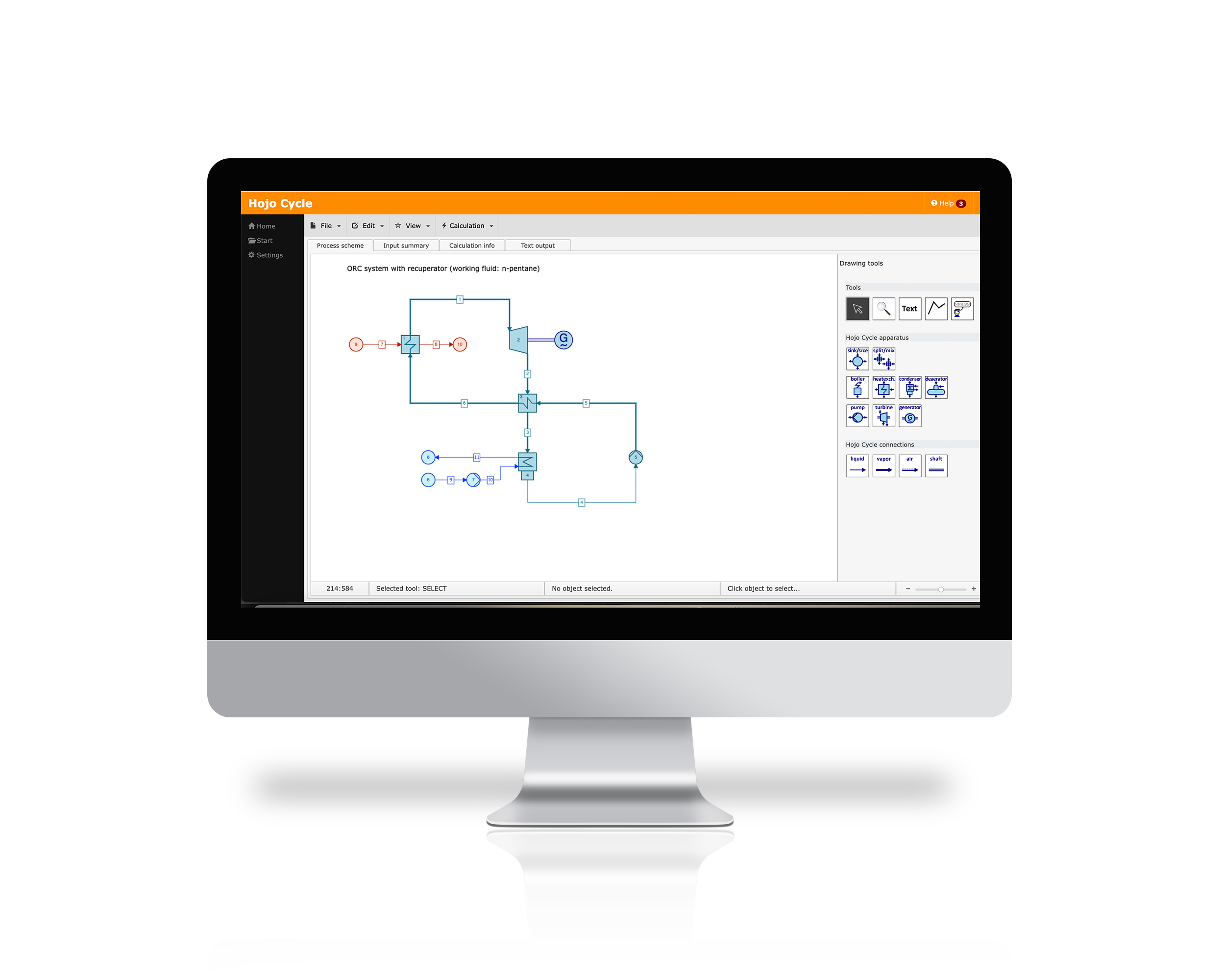

What could this mean for Asimptote? A kind of online version of Cycle-Tempo? Yes, indeed!! We are working on it already for quite some time (Hojo Cycle project) and soon a demo/trial version will be released.

Keep an eye on the news items on our website and the on Facebook, Instagram, and LinkedIn posts. The user interface has been written in JavaScript and resides with an NodeJS server and the famous Fortran calculation kernel on a Linux server. On your side, Hojo Cycle runs in your browser (e.g., Safari, Google Chrome, Firefox, Windows Edge). Can you imagine running Cycle-Tempo on your tablet, or even on your smartphone? STAY TUNED!

Teus van der Stelt

February, 2023